Insight Rolex: What does it take to service a vintage Rolex properly?

Fine WatchesCollector's InsightWe all love vintage Rolex. We love doing research on it. Discovering the details of Rolex. And most of all we love buying vintage Rolex and enjoying the pleasures it gives us.

But when it comes to servicing vintage Rolex we don’t become so enthusiastic about it anymore.

First there is the problem of cost.

Vintage Rolex is notoriously expensive if you want to get it to done at Rolex. But that is not the main problem. The main problem is the risk what Rolex does to your vintage watch once they receive it. Do they respect your instructions? Will they respect the heritage and history of the watch? Do they even know the heritage of the watch? This is what scares me the most when I send it in. I have heard that they have made big improvements in this area but I have still heard stories that will make you fall off your chair.

So rather than take any risk, I send it to my watchmaker. He has been servicing and dealing with watches almost as long as I have been on this planet and I know with him – I have a safe pair of hands. Another benefit of sending it to him is that I can follow along exactly what is being done. I recently sent my 1953 Rolex Explorer 6350 Honeycomb dial for service and this is what happened.

Let me share the experience with you.

(For an in-depth report on the Rolex Explorer 6350 honeycomb dial – please see our report here).

First part: Overall analysis of the watch.

The first step of the watchmaker involves an overall analysis of the watch.

What are his first impressions? The watch tells him a story of the life it lead in the past. What is the condition. Was it polished? It is original? Is the dial original? Did humidity get into the dial? Was the watch looked after? Does the condition make sense (for example a pristine dial but banged up scratched case is not consistent). Does it show oxidation? Is the watch dirty from the sweat of the owner (btw did you know that sweat can eat its way into the case if it is steel and cause rust with time).

Included in the overall exterior analysis is setting the watch. How does the watch react to setting the time (moving the hour and minute hands). If the centre bearing of the watch is worn out it shows that the watch was probably worn along time without being serviced.

The next step involves a superficial analysis of the movement by just opening the case back.

Did the watch get scratched during service when another watchmaker re-assembled the plates and bridges? Are there any service signs in the caseback? Did humidity get into the movement? How are the condition of the screws? If they are scratched it could mean the watch maker was not as careful as he should have been.

So you see- also the movement tells a story of the watch, how it was looked after before it arrived to the watchmaker.

Lastly the watchmaker looks at the balance wheel and the balance spring (breguet spring) of the watch and how it turns and the condition of the spring. This is important because the balance wheel determines the accuracy of how the watch keeps time.

Depending on all these factors the watchmaker will either accept a restoration or not. Only once this process has been done, does the watchmaker actually begin with the restoration and service of the watch.

Second part: Disassembling of the entire movement and case

The first step in the second part is to dismantle the watch and movement. Notice the rust that has got into the case of the watch over the years. It is estimated that this 6350 Explorer has not seen a service in over 10 years.

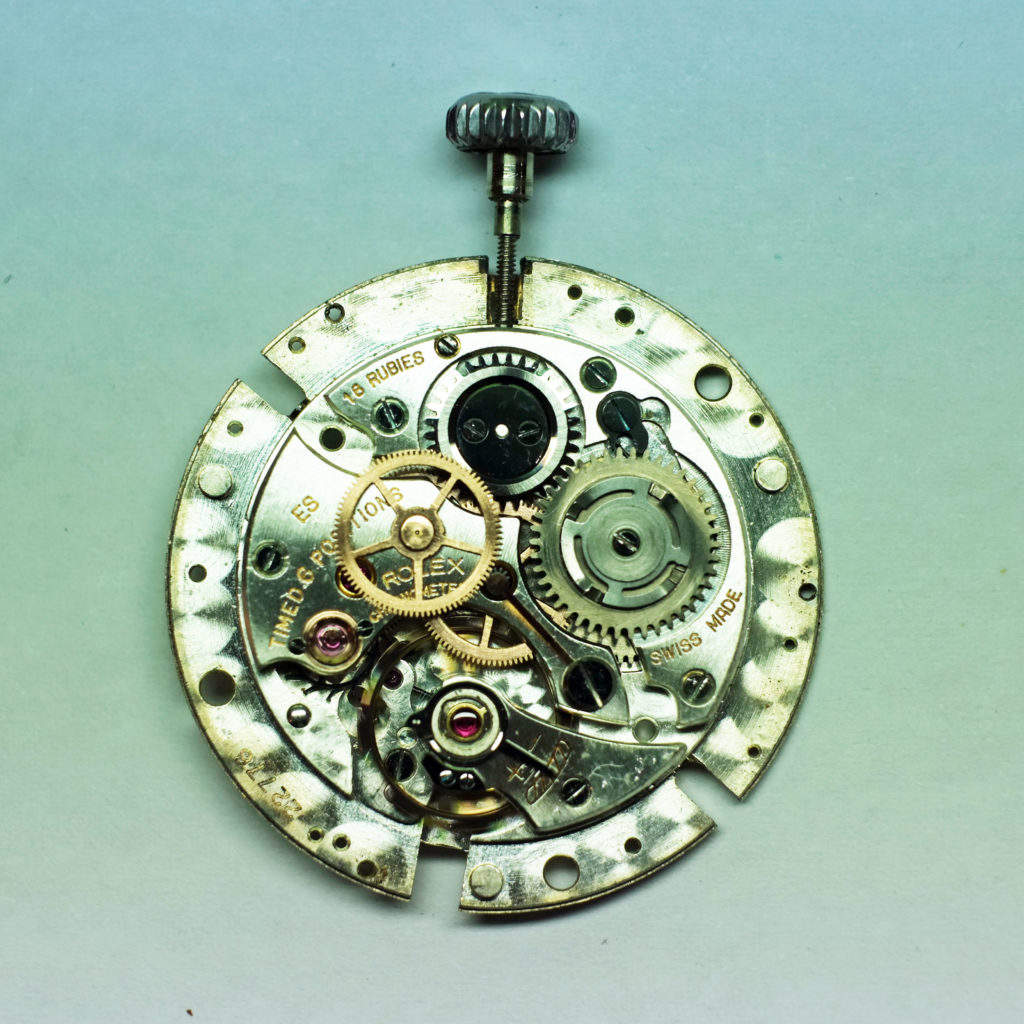

The movement is taken out of the case and an analysis is done.

Notice the dirt around the edge of the movement, this is the back part of the movement. These parts are exposed to excessive wear and tear given they are exposed to force daily when the owner winds his watch.

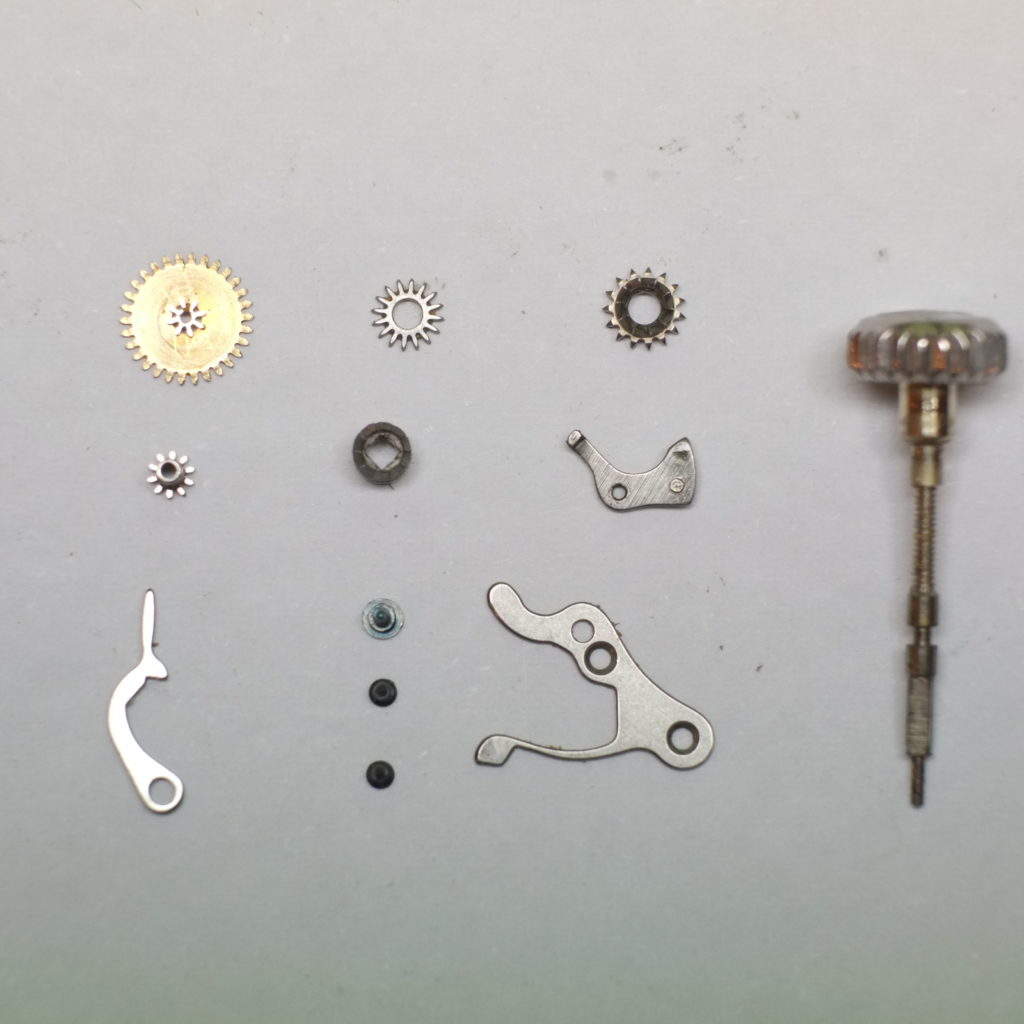

The movement gets completely taken apart. Every single wheel and screw.

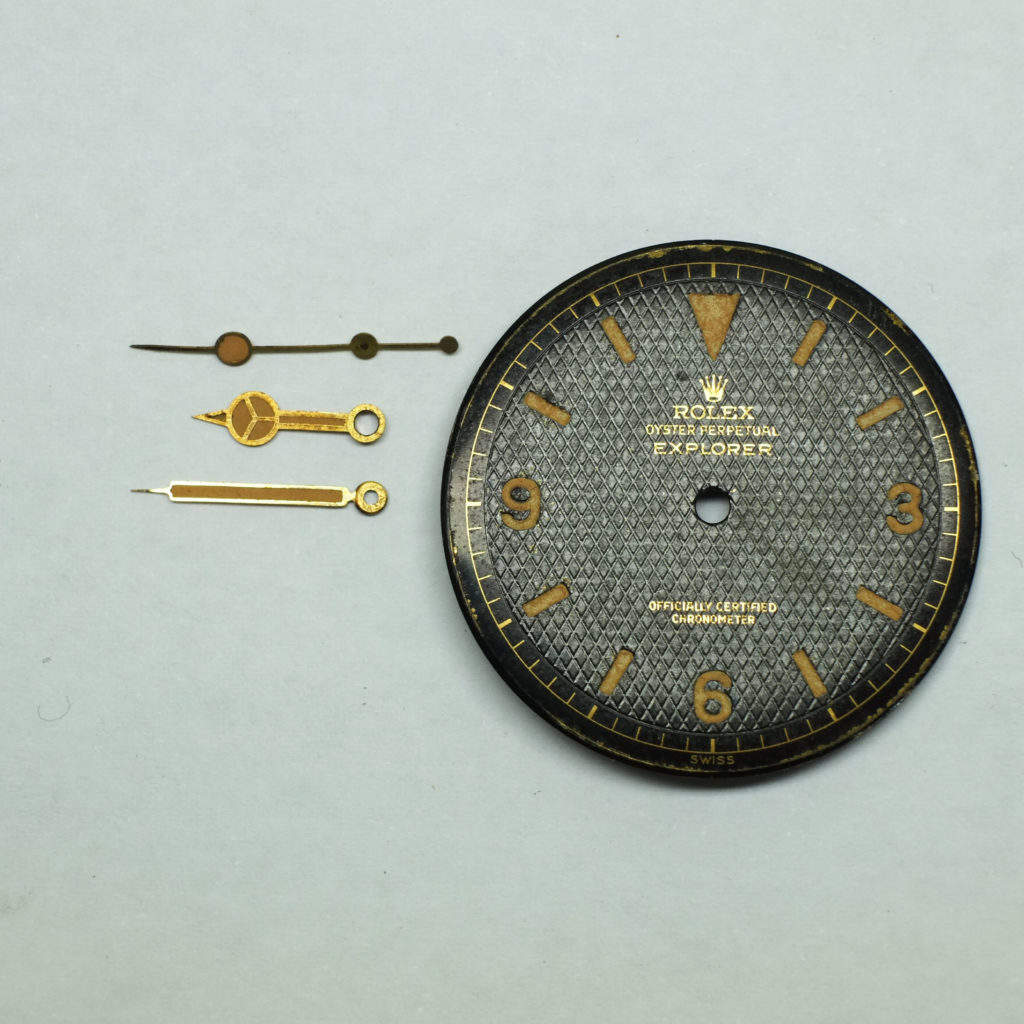

Here the other side of the movement, the front part where the dial gets mounted and hour and minute hand placed.

Once dismantled there are hundreds of parts everywhere like it should be.

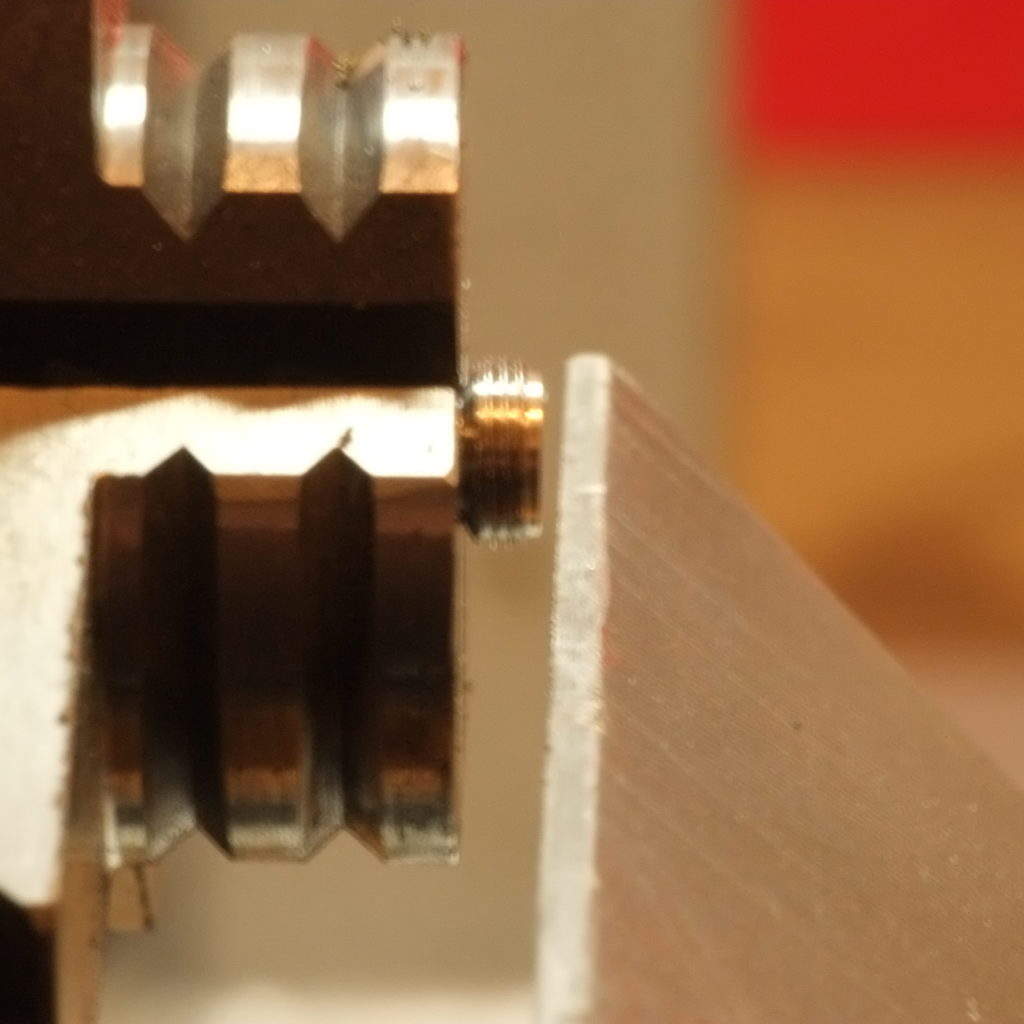

Below some of the winding parts, used to wind up the watch. All parts are checked are carefully. These are also the parts that most exposed to be worn out because of constant use. Setting and winding constantly has its negative effects (pulling out the crown, winding the watch, setting the watch).

Below some of the winding parts on the side of the dial, you can see the winding crown on the right.

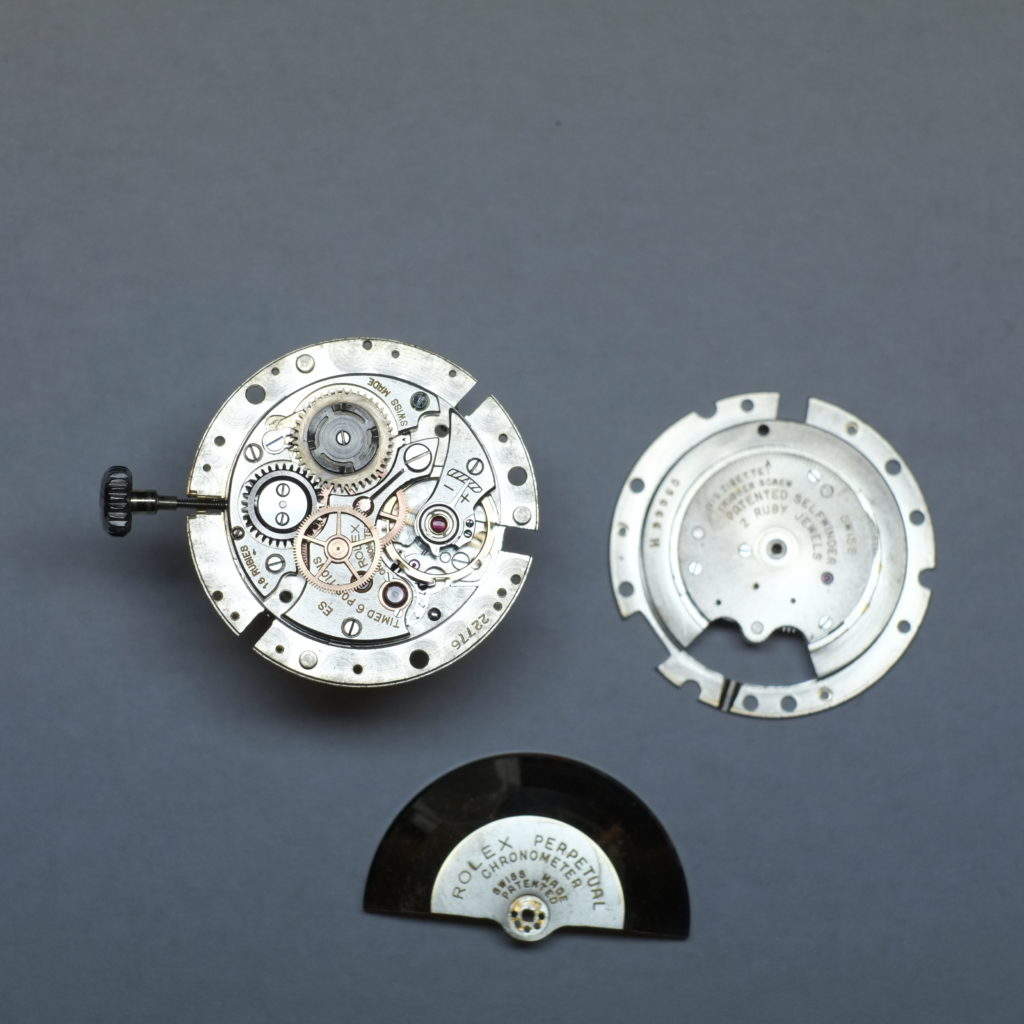

Notice also that the rotor that is dirty (notice the brown on it – what seems like rust) and the back of the movement showing the winding side. This is before it is cleaned.

Vintage watches with time get dirty, take on sweat and grease from the owner and it is very natural for rust to develop around the dial and also in parts of the movement.

Look at the case below and see the rust that developed around the edge.

Then the case bezel and plexi are all cleaned including every screw and every part.

Below the ultrasonic cleaning system. The case can be seen below.

The dial is also dismantled and carefully checked.

After the cleaning process is done it is time for a re-assmembly.

Below the movement being reassembled again. Screw by screw.

Below the cleaned case can be seen, now free of rust and grease.

The movement is now clean and ready to be put back together.

Below you can see the back of the movement, the winding part. Also the rotor is shown below. Notice the brown shade that you saw before is gone on the rotor and the movement is sparkling clean

The Breguet spiral (or overcoil) can be seen below.

The condition of this Breguet spiral is critical as it is responsible for allowing the watch to keep good time. The pieces below are the heart of the watch – and it is this spiral which will dictate the beating of the movement and thus the accuracy of the watch. On the right the regulator with the (-) and (+) signs.

Notice all the screws and every single part that is now clean and ready to put back together again. There are 81 components in the picture below. Every single one of them was cleaned.

A special machine is used to help put the hands back on the dial with pressure. It can be seen below.

Sometimes certain parts have to made smaller again. In this case the tube of the crown- as the crown was not turning correctly and there was a gap between the crown and the case which should not be. So the tube was shortened.

The case is also checked and cleaned. The plexi is checked to make sure the watch is waterproof.

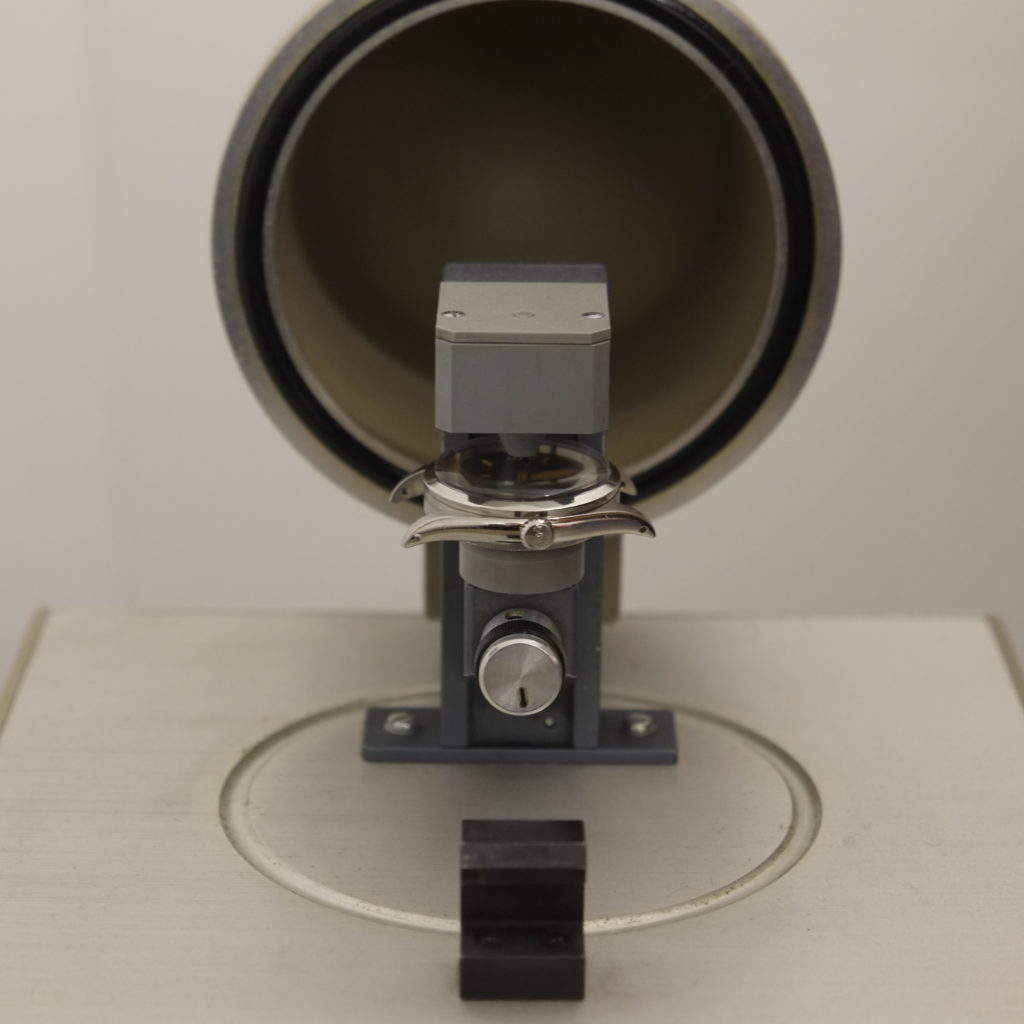

Below the machine use to test the water resistance (today this is done with pressure- it used to be done with water). The green light means it is all good.

Another view of the machine checking water resistance, which is a piece of art in itself. The machine is from the 1980s.

The watch is carefully placed inside the tube of the machine and then tested for accurate water resistance. The re-assembled watch can be seen below.

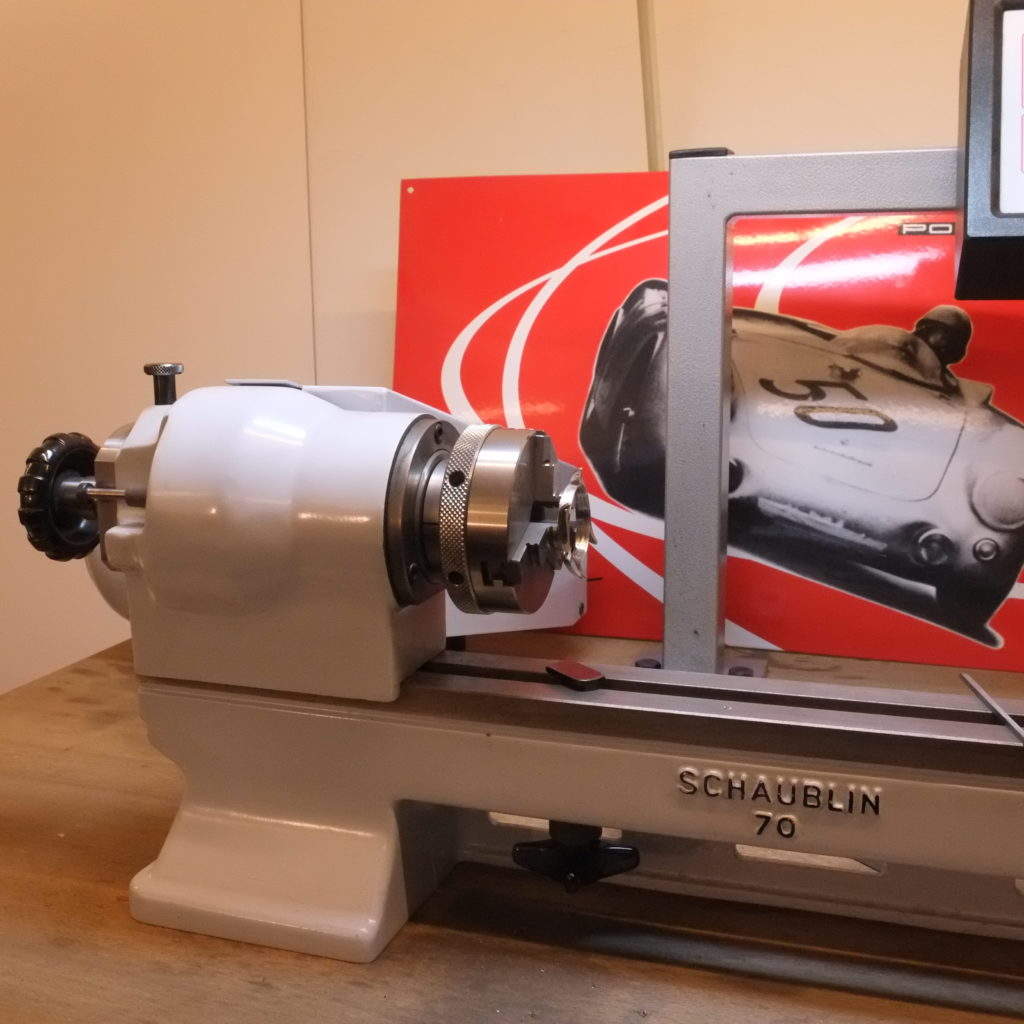

The case is carefully checked and and below the rust is removed from the case, using what is called a laethe machine. You can see the case on the end of the machine, a schaublin 70 – which is considered the RR of these machines.

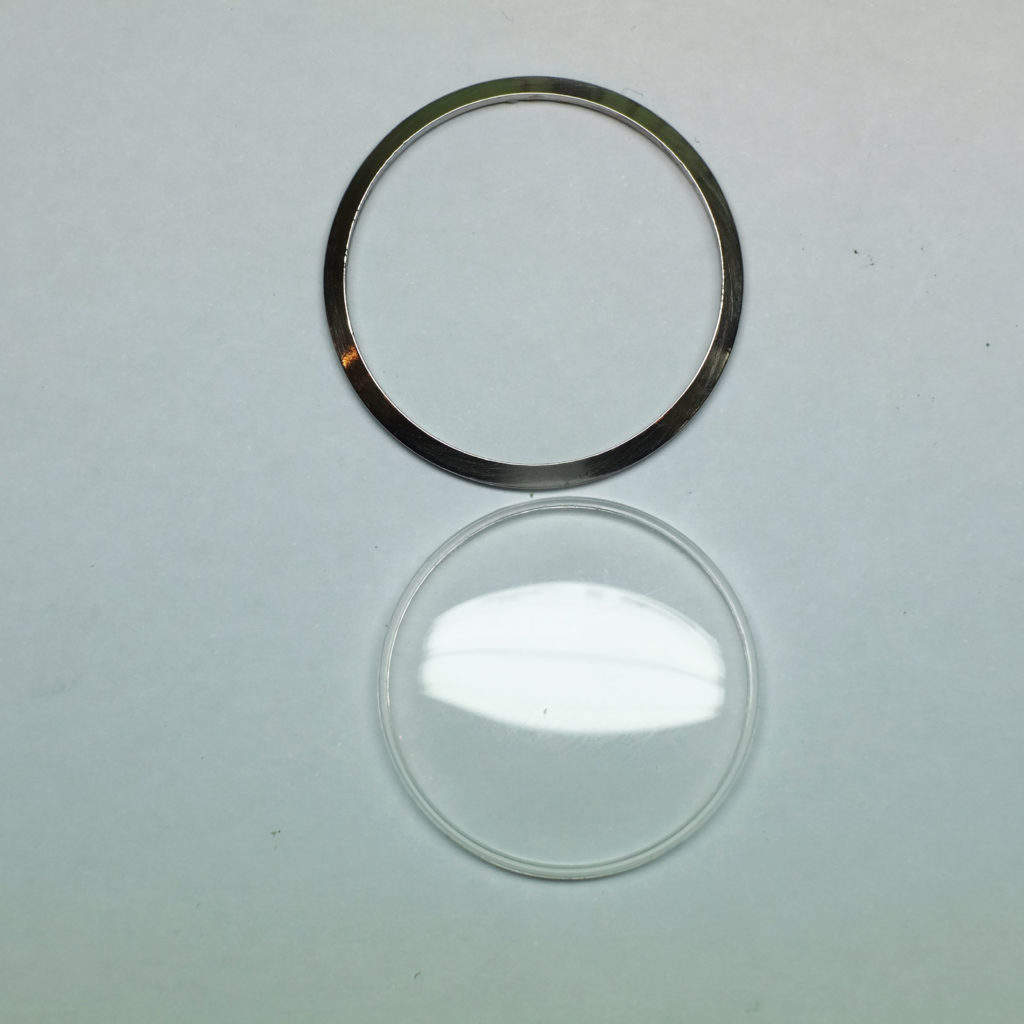

The plexi and the retaining ring carefully checked as well. The plexi is then lightly polished to get rid of the scratches. As I am sure you are aware plexi looks better than sapphire crystal but is unfortunately more prone to get scratched.

After the watch is put back together, it is tested for timekeeping

Watches are like cars they need regular maintenance. That includes servicing and making sure the watch keeps time accurately. Before I sent the watch in – it was losing at least 3-4 minutes every day which is of course not acceptable.

Below a Vibograph. This is a machine used to test the accuracy of the watch in different positions. You can see the movement of the 6350 below on the Vibograph.

After the watch is checked for time-keeping accuracy it is then put on a winder for one week to double check it is not losing time. A good ten days go by when it is ready to be worn again with perfect accuracy.

Here a shot right after I picked it up from service.

Closing remarks

I don’t like giving any of my watches for service.

Everyday that I am without one of my watches is like a form of punishment. I will only have them a limited time in my life anyway and so I try and wear and use them everyday. I don’t like parting from any of my watches.

However, watches are like cars – you need to service them properly every few years or you risk serious damage. Movement parts can break if not oiled and cleaned. And watches lose accuracy with time.

Servicing vintage watches is admittedly very tricky.

Too many people don’t know what they are doing. And they don’t respect the history and heritage of the watch. Or when they do the bills are astronomical and the waiting times unacceptable. In this case I waited two weeks which are very acceptable and paid a bill of around CHF 2’100 for a complete service (Rolex would charge a sum at least twice to two and a half times that) with the risk of the instructions not being carried out correctly. I have been lucky to find a watchmaker who is also a dealer and has been involved with vintage watches for over 30 years.

He knows how watches were born and respects their history.

Do yourself a favour. The next time your are examining a watch for potential purchase – take a look at the movement. Open the caseback and look inside the watch. It will tell you a story that most people ignore.

Most collectors (myself included) are only concerned about the case, and the dial and forget to look at the movement and the history the watch went through. Is the movement dirty or shiny? Are the screws scratched? Is there rust visible? Is the movement condition consistent with the rest of the watch? For example a movement that is dirty not cared for and scratched with service marks in the case-back together with a pristine dial and perfect case without scratches should be a warning sign.

My point is that the inside of the watch also tells a story. Most collectors chose to ignore the story and only bring in a watch into service when the watch starts losing time drastically or stops all together.

A strategy that is not advisable at all.

(NB: My watchmaker responsible for the complete service of my 6350 Explorer is Jim Gerber. You can follow his Instagram account here). All picture credits for this blog post except the last one belong to Jim Gerber.